E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

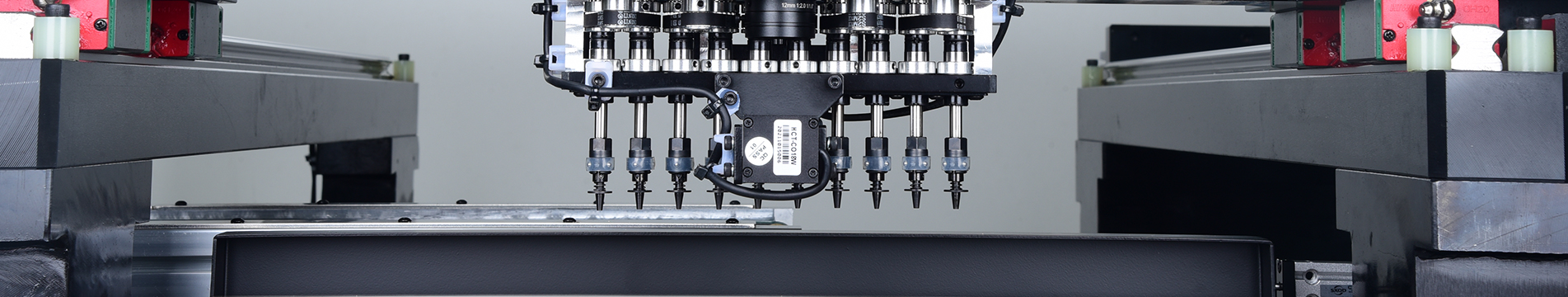

Automatic Visual Profiled PLUG-IN Machine HCT-YX540

HCT-YX540 automatic visual-profiled plug-in machine fully adopts the XY structure of an SMT mounter with high precision and fast processing speed. Compared to manual plug-ins, it has advantages like higher efficiency, a higher automation rate, better quality, and lower labor costs. The back frame seat is made of electroplated steel tube to ensure high strength and durable operation.

Product Description

This is a plug-in machine with full automatic operation and visual profiling technology. It is suitable for all types of circuit boards and chips. It can replace manual plugging and realize high efficiency, high quality, and fast production speeds. There are more feeder slots for multiple types of materials, which makes it easy to change production lines. The chair base uses a high-quality electroplated steel frame with a leather contact surface, which provides a comfortable seating experience.

Product Parameters

|

Model |

HCT-YX540 |

|

Plug-in Shaft |

4 |

|

Insertion Speed |

0.45S/PC (Gripper/ Vacuum) |

|

Repeatability Accuracy |

±0.02mm |

|

Insertion Accuracy |

±0.03mm |

|

Component Size |

3-40mm |

|

Component Height |

25mm |

|

Component Range |

USB/Connector/Lug/Switch/Resistor/Inductor/ Transformer/Coil/Chips/Cells, etc. |

|

Insertion Direction |

0-360° |

|

PCB Size |

50*50-500*350mm |

|

PCB Thickness |

0.8-5.0mm |

|

PCB |

Inline Conveyor L-R or R-L,3-Section Transmit |

|

Feeder Station |

8 Slots |

|

Feeder Type |

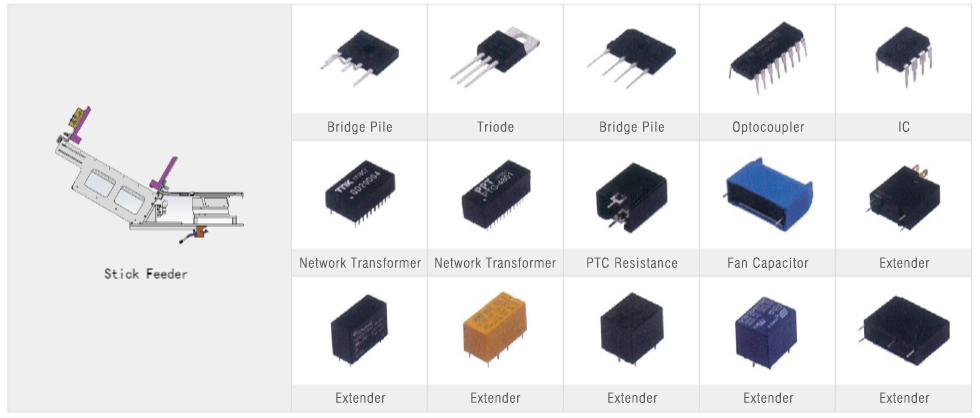

Bulk Feeder/Tape Feeder/Stick Feeder/Tray |

|

Material Taking Method |

Gripper/Nozzle (Optional) |

|

Power Supply |

220V 50Hz |

|

Power Consumption |

3.5KW |

|

Air Supply |

0.5±0.05Mpa |

|

Dimension |

1440(L)×1600(W)×1500(H) mm |

|

Approx. Weight |

1350KG |

Product Features

- Replace manual plug-in, realize full automation, high efficiency, high quality, high speed plug-in

- Adopt the XY structure of the SMT mounter, with high precision, fast speed, and strong expansibility.

- PCB mechanical positioning + visual MARK point positioning to guarantee high accuracy

- Fast production line change, with more feeder slots for multiple types of materials

- Compact independent feeder with strong versatility and easy to replace

- Different corresponding solutions can be designed according to the components in 4 different packaging methods: vibrating bowl feeder, tape, stick, and tray

The rack is effectively treated to ensure the service life of the equipment and its stable plug-in and accuracy.

Product Display

|

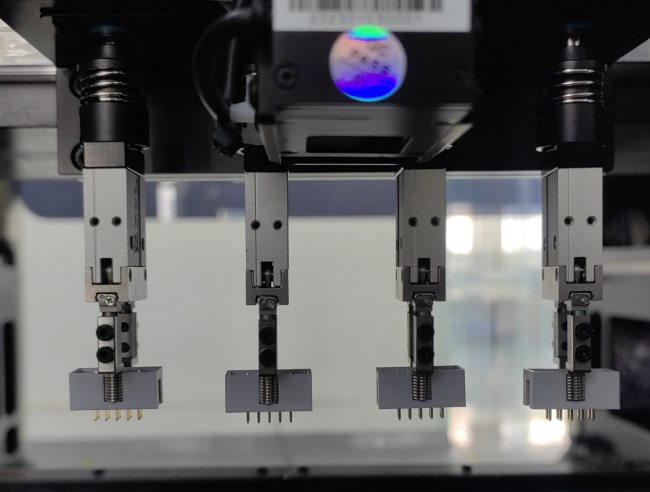

Gripper |

|

|

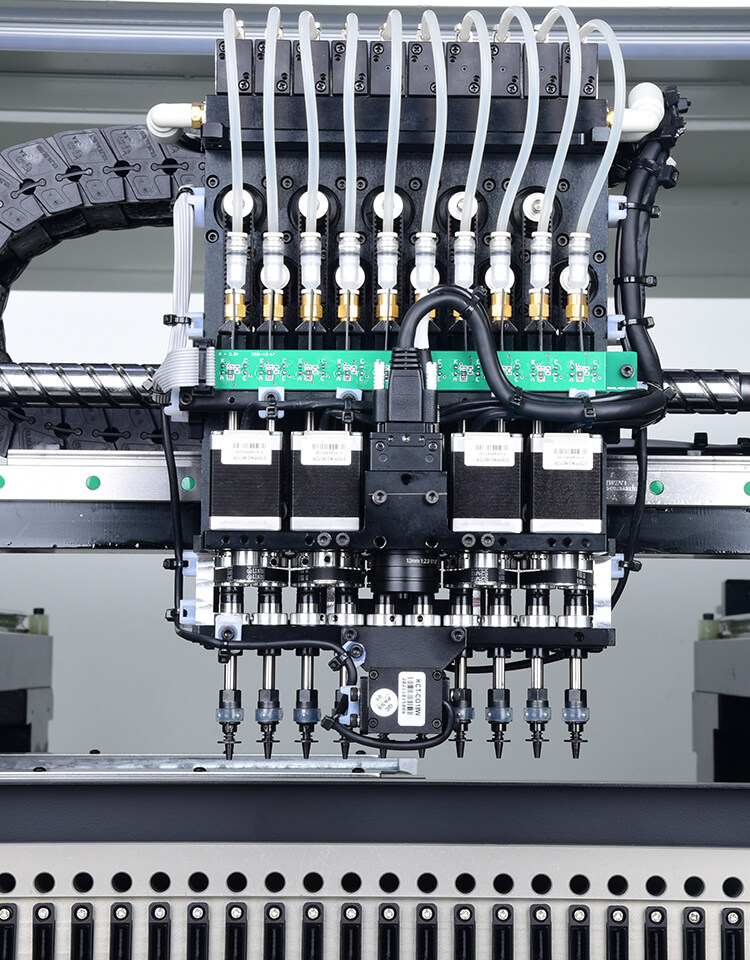

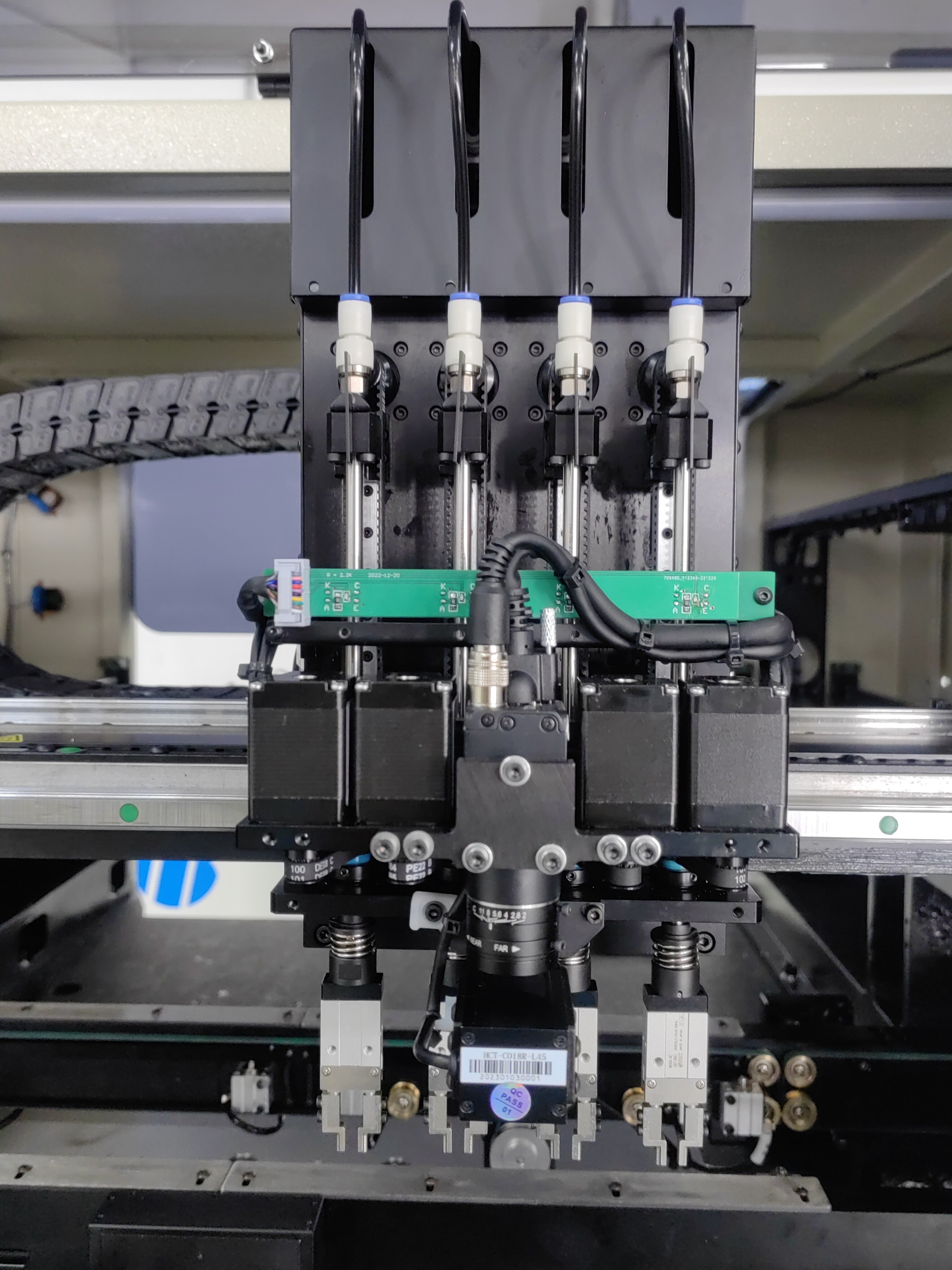

Head Part |

|

|

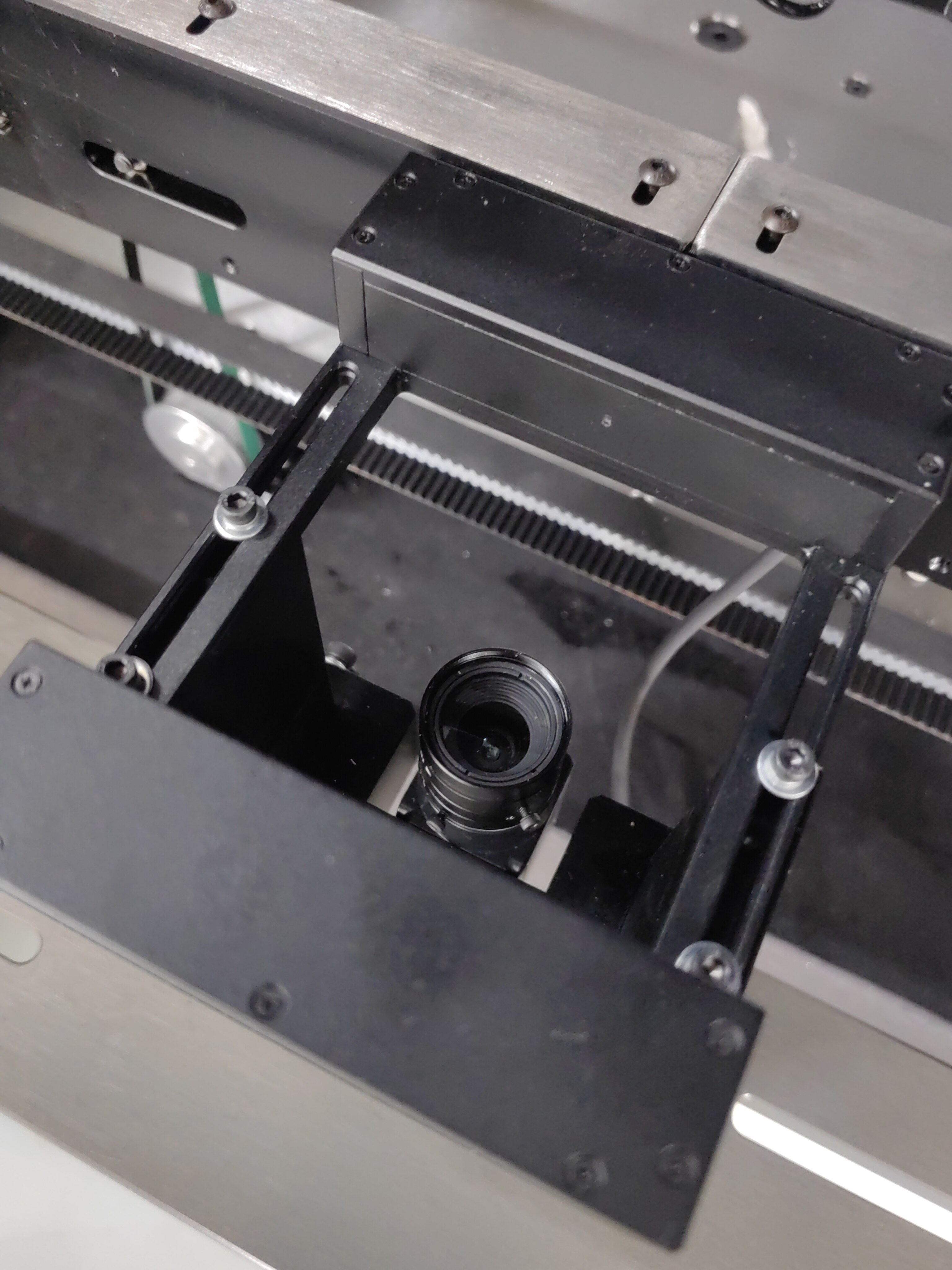

Vision Camera |

|

|

XY Linear Motor |

|

Plug-in Materials

Product Advantages

1. High-speed, high-efficiency design

HCT-YX540 automatic visual-profiled plug-in machine fully adopts the XY structure of an SMT mounter with high precision and fast processing speed. Compared to manual plug-ins, it has advantages like higher efficiency, a higher automation rate, better quality, and lower labor costs. The back frame seat is made of electroplated steel tube to ensure high strength and durable operation.

2. Specifically designed

The HCT-YX540 automatic visual profiling plug-in machine is a high-efficiency, large-capacity plug-in machine that can be well integrated with most of the machines used in a complete production line. The XY structure of the SMT mounter is adopted, which realizes high precision, fast speed, and strong expansibility. PCB mechanical positioning + visual mark point positioning to guarantee high accuracy and fast production line change, with more feeder slots for multiple types of materials. Compact independent feeder with strong versatility and easy to replace.

3. Software simplifies production

This is a plug-in machine with full automatic operation and visual profiling technology. It is suitable for all types of circuit boards and chips. It can replace manual plugging and realize high efficiency, high quality, and fast production speeds. There are more feeder slots for multiple types of materials, which makes it easy to change production lines. The chair base uses a high-quality electroplated steel frame with a leather contact surface, which provides a comfortable useing experience.

4. Reliable Performance

Stable and reliable performance, equipped with the wireless remote controller, makes the high-speed feeder plug-in machine easy to operate, and the plug-in speed is adjustable. A high return rate can meet the production of various shapes of products with different requirements.